Flange Integrity Management Toolbox

Eliminate losses due to leaking flanges during start-up and up to one year after TA

“If you do it right, each flange is tight.”

Might sound strange, but it is true. Always.

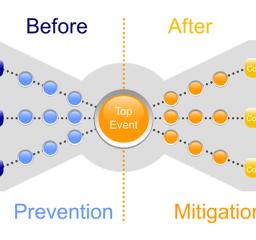

Flange leaks result in start-up losses. To prevent this from happening, PDM has developed a complete improvement program: Flange Integrity Management (FIM). With this approach, we guarantee our customers that they do not suffer any start-up losses due to flange leaks and no leaks during the first year as a result of the activities in the turnaround (TA).

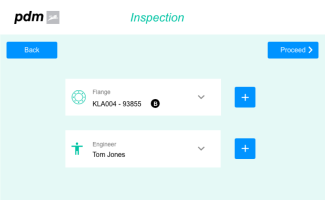

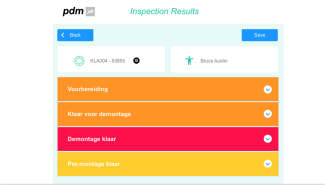

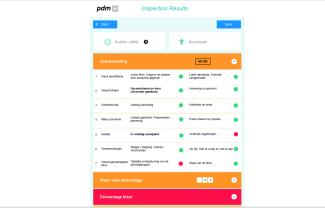

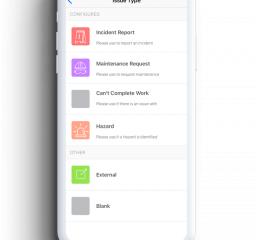

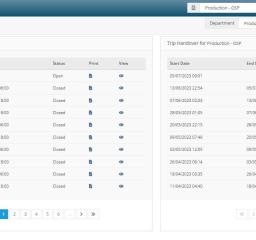

Our FIM Toolbox contains all tools your organization needs before, during, and after a turnaround. The FIM approach has proven itself in recent years. Based on these experiences we have created a new version of our FIM Toolbox, in which management and steering information is available even quicker. Possible quality threats can be managed more efficiently by applying a special app for registering FIM inspections.

On the total budget of a turnaround the costs of applying FIM are minimal. Especially compared to the considerable savings potential that can be achieved (no start-up delays, substantially less re-work, no unplanned stops…). Based on the specifics of your organization and the planned maintenance efforts, we can discuss the positive business case to see which potential FIM can achieve. FIM improves quality and safety, and by doing so also saves money.

| Specification Title | Specification Description |

|---|---|

|

Areas of Application

|

(Petro)chemical industry, pharma and civil engineering.

|

|

Certifications / licences

|

PDM provides the necessary training for staff and contractors for FIM to be applied successfully. FIM trained personnel will receive a certificate.

|

|

Compliance

|

NEN-EN 1591-4:2013 compliant

|

|

Content

|

Training material | FIM Manual | FIM Quick Reference Book | FIM Inspection app | FIM Dashboard tool | Integrity Test

|

|

Input

|

List of flanges in scope | List of contractors and staff | Users for FIM Inspection app | Dashboard access

|

|

Output

|

Reviewed and updated flange information | Inspection results | Dashboard with real-time data for managing contractors | No start-up losses

|

|

Return on Investment

|

Typically, one day of start-up loss is more expensive than applying FIM during a stop.

|

|

Time on tools

|

As a result of applying FIM, a higher Hands on Tool Time (HoTT) is achieved.

|

Reviews (1)

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[9/9]

Relative Business Impact

Sign up or log in to your explorer or higher plan to get access to all the 1 deployment references.

Last Deployment Year