Verification of permanent P&A barriers for wells

A quick, unambiguous and versatile method to verify integrity of a wide variety of downhole barriers

Exedra AS has developed a new way to verify whether a dowhole barrier is leak tight. The method is quick, unambiguous, versatile, and allows the operator to test in the direction towards the external environment. The method applies a well known, and mature technology from other industries, releasing a tracer gas below the barrier to be tested, and 'sniffing' above, to detect any possible leaks aross the barrier. The method allows the operators more flexible, lower cost solutions, enabled by lowered risk and acceptance from regulators. This will result in cost reductions, and at the same time reduced risk of leaking abandoned wells. Examples include shorter creeping shale barrier, barrier across double casings, verification of PWC plugs, shorter section milled section, etc. The current design uses Helium as tracer gas, and detectors in flow line provided by third party, typically a mud logging company. The Helium tracer gas can easily be interchanged with an alternative tracer gas if needed. Exedra has demonstrated the technology together with Geolog International's modified gas detection system, and shown consistency and extreme sensitivity. The method can also be used to qualify barriers for future CO2 storage.

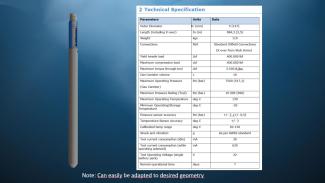

| Specification Title | Specification Description |

|---|---|

|

Length (including X-over)

|

2,5 m

|

|

Diameter

|

127 mm

|

|

Max operating pressure

|

7500 psi

|

|

Max operating temperature

|

130 deg C

|

|

Normal operating time

|

7 days (can be increased significantly)

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[6/9]

Relative Business Impact

Sign up or log in to your explorer or higher plan to get access to all the 1 deployment references.

Last Deployment Year