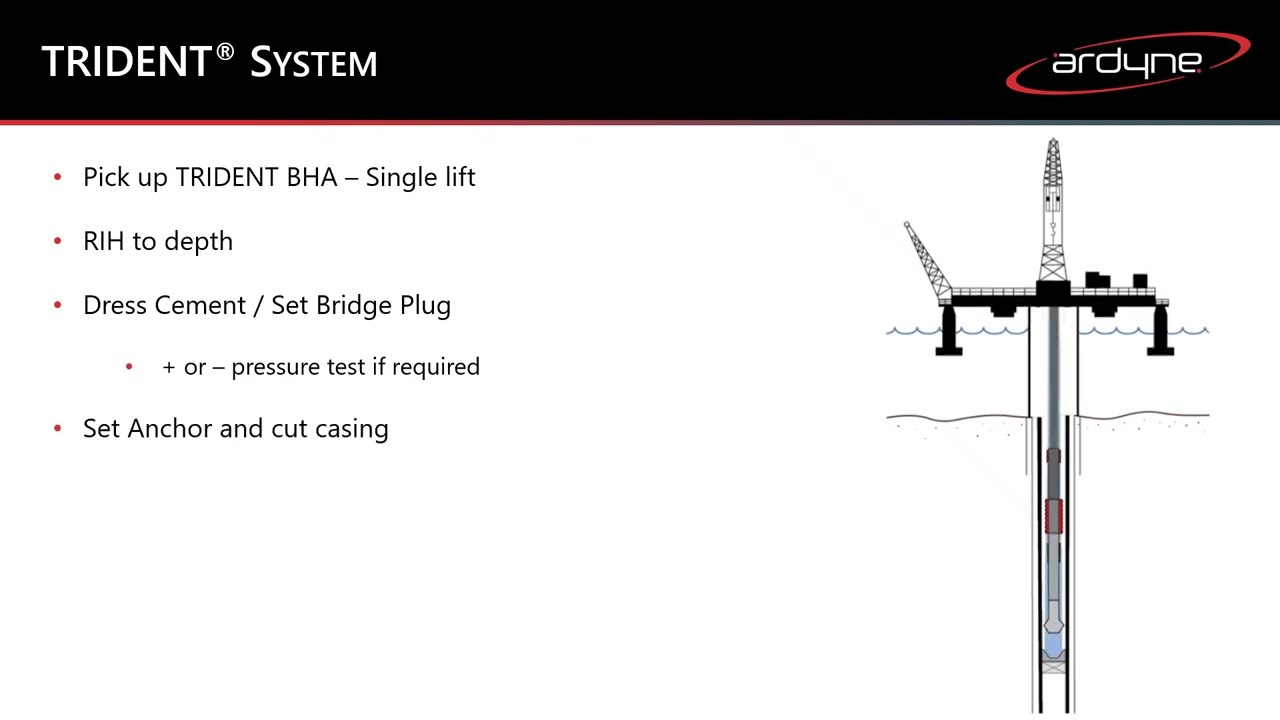

TRIDENT System

Integrated casing cutting and pulling system with single trip functionality

TRIDENT - a modular rotary driven, single-trip cut and pull system that incorporates several innovative trip saving features including an integral tension set packer and a hydraulically activated spear in conjunction with the ability to either run & set a bridge plug or dress a cement plug prior to commencing the cutting and recovery of the target casing.

TRIDENT has inbuilt extras including: cut verification capability; a swarf management system to avoid swarf entering sensitive well control equipment; a spear which sets in both 9-5/8” and 10-3/4” sizes for tapered casing; annulus circulation around the cut casing, and other features.

The next generation, the Shogun System, is built on the same qualities of TRIDENT but also includes cement thru capabilities. Enabling single trip operations to set a Bridge Plug, place Cement Plug & test, cut casing and recover to surface.

| Specification Title | Specification Description |

|---|---|

|

Casing Cutting

|

Ability to make multiple casing cuts on the same trip

|

|

Annulus Circulation

|

Circulate out gas or debris from annulus prior to pulling casing

|

|

Set & test a Bridge Plug

|

Complete on the same run as casing cutting, removing need for dedicated trip

|

|

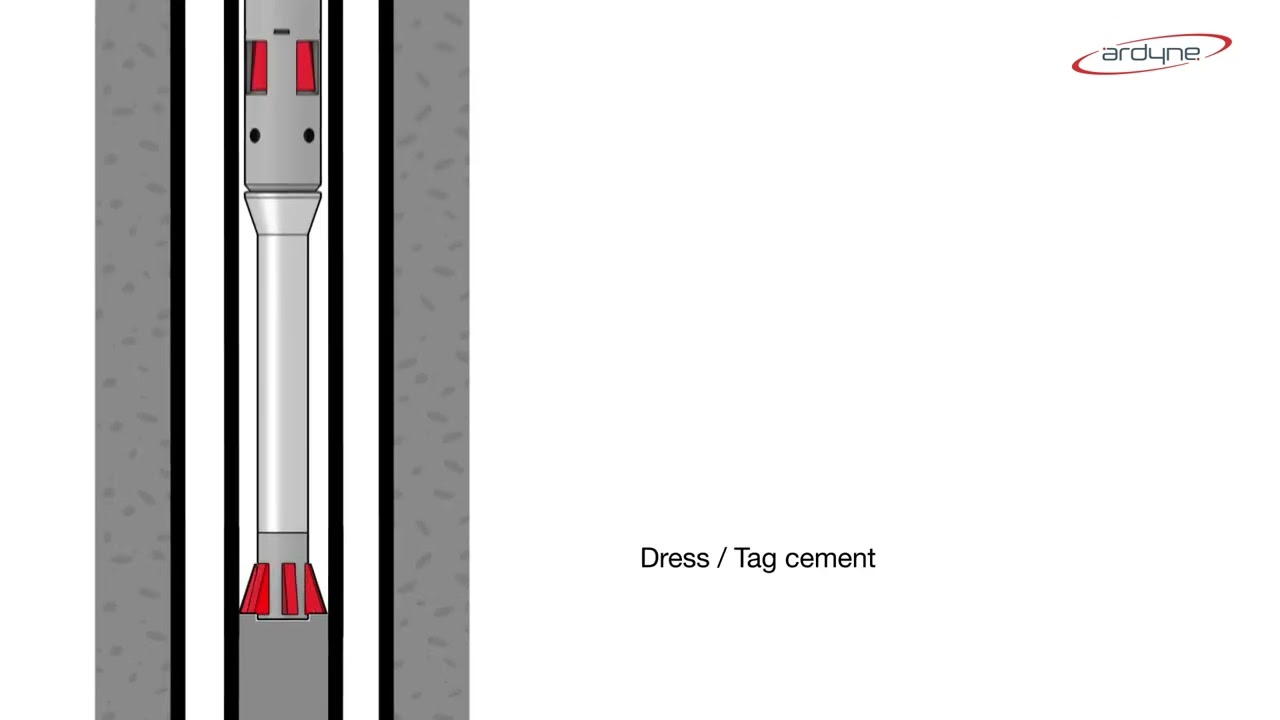

Tag / Dress Cement Plug

|

Cement plug can be tagged / dressed before commencing casing cutting operations

|

|

Test Pull Casing

|

Verify casing cut by picking up at depth before relocating to hanger

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[9/9]

Relative Business Impact

Sign up or log in to your explorer or higher plan to get access to all the 345 deployment references.

Last Deployment Year