Superior Vane Inlet Device

Maximising (bulk) liquid separation & gas flow distribution

In a facility processing multiphase fluids, most of the challenges that occur as the result of excessive liquid carry-over, can be traced back to the upstream vessel: (1) Poor gas-liquid separation at the inlet device, (2) Incorrect selection of the mist eliminator and its configuration for the particular service, and (3) Insufficient liquid handling capacity in the mist elimination section. A properly selected and designed inlet device is the most important vessel internal and a primary requirement to achieving a high overall gas-liquid separation efficiency and therewith minimise liquid carry-over.

Bulk liquid separation

In all process lines that handle a gas & liquid multiphase fluid, depending on the flow rates, fluid’s properties and line size, a certain flow regime will be established. Subject to this flow regime, a certain fraction of the liquid will become entrained in the gas phase as droplets with a certain droplet size distribution and the other fraction will remain present as bulk liquid. Hence, the bulk liquid can be considered to already being separated from the gas phase. It is therewith of utmost importance to ensure this multiphase flow enters the separation vessel as smoothly as possible and any increase of shear imposed to this fluid (e.g. through impingement) is to be avoided at all cost.

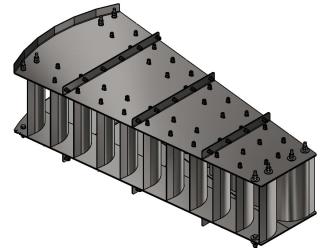

This is realised by using a Superior Vane Inlet Device: the mixture velocity upon entry to the vessel is significantly reduced by the large open area on both sides of the device. The fraction present as bulk liquid will exit the device between the vane blades and drop down to the liquid level under the gravity forces acting and the fraction present as droplets will be carried along with the gas. In terms of liquid removal, this is by far the largest contribution to the overall separation performance and which is achieved very effectively and efficiently!

Gas flow distribution

The Superior Vane Inlet Device has large open areas on both sides of the device. This not only reduces the mixture velocity significantly, its vanes also guide the gas evenly over its entire length smoothly into the gas-space of the vessel. This is a prerequisite for the gas to become evenly distributed over the entire cross-sectional area available for gas flow, as well as avoid adverse gas flow effects such as liquid re-entrainment, etc.

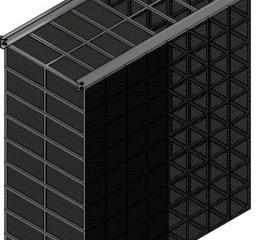

When the gas is evenly distributed, the best performance is achieved with respect to liquid droplet separation from the gas by gravity. The less liquid arrives at the mist elimination equipment, the better it is for the overall separation efficiency.

| Specification Title | Specification Description |

|---|---|

|

Available sizes

|

Tailor-made to be compatible with inlet nozzle size.

|

|

MOC (SS)

|

304, 316, 321, 904

|

|

MOC (Duplex)

|

S31803, S32205, S32750

|

|

MOC (Alloys)

|

C276, 400, 625, 825

|

|

MOC (Other)

|

Other materials of construction upon request.

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[9/9]