Remote Control & Assisted Autonomy

Remotely monitored autonomous crane operations

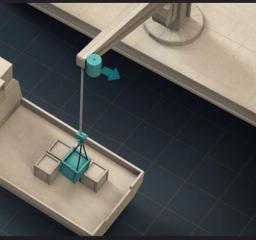

Since late 2017, Aker BP and Optilift has collaborated on developing technology for remotely monitored autonomous offshore crane operations. The development has been performed in stages, maturing the technology readiness level (TRL) where among other a model crane, simulator and an electric lattice boom offshore crane from has been used to test and demonstrate the technology.

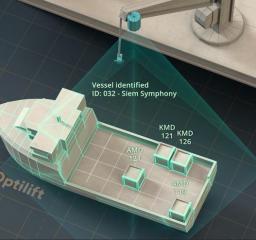

The autonomous crane control system from Optilift is supporting Aker BP’s mechanical AutoHook concept, and is set up to be able to perform lifts of cargo without the need for human interaction. After successful demonstrations of the technology using the model crane in 2019, full-size crane testing and further maturation of the technology was performed onshore during 2021 and thereafter offshore during 2022.

After the lattice boom crane was installed offshore at the Valhall field of Aker BP, testing and optimization of the Optilift solution continued throughout 2022. The tests started with gradually increasing complexity on the loading decks on the rig, to confirm the assistance systems and autonomy, before moving onto tests in calm weather conditions on a supply vessel.

The technology can be retrofitted to existing cranes, or integrated by the OEM with new cranes. Optilift provides sensors and software technology that allows safe remote-controlled crane- and lifting operations, which can be further extended to autonomous lifting and logistics handling.

By remote controlling crane- and lifting operations, it is possible to allow one crane operator handle multiple cranes at different sites. This means reduced travel costs, increased safety, and efficiency. In times where it may be difficult to source qualified personnel, or travel restrictions are enforced, crane operations may still take place without delays.

| Specification Title | Specification Description |

|---|---|

|

Areas of Application

|

Cranes located on- and offshore, in ports, harbors, on vessels, wind-mills etc..

|

|

Cargo handling

|

AutoHook concept enables personnel-free decks.

|

|

Usability

|

Safe and intuitive remote control by the use of Optilift Assistance Systems.

|

|

Safe operating

|

Auto lift-off, auto landing, anti-pendulum and anti-collision Assistance Systems ensure safe operation even in case of network connectivity issues and human errors.

|

|

Motion compensation

|

Auto Landing, Auto Lift-Off, Relative Heave Compensation, Anti-Pendulum and AutoHook control ensures controlled and partly automated complex lifts.

|

|

Versatility

|

Integrates with Digital Logistics solution to automate planning and tracking of lifting plans and cargo locations.

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[6/9]

Relative Business Impact

Sign up or log in to your explorer or higher plan to get access to all the 1 deployment references.

Last Deployment Year