The Lean Machine: True Multi Modular Rigless Solution for Workover and Drilling operations

Light, Configurable, Modular, Robotic Solution

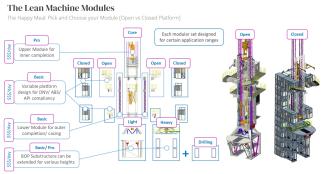

The Lean Machine is a pioneering solution addressing core challenges within the offshore energy sector, with a primary focus on reducing significant cost drivers associated with well decommissioning, notably those influenced by rig-related activities like pipe handling and hoisting. This innovative technology centers around a modular concept, based on a core workover unit, which can dynamically expand or contract its operational capacity by adding or removing task-specific block structures. This approach offers unprecedented versatility, modularity, and adaptability, ushering in a new era of efficiency, safety, and environmental performance.

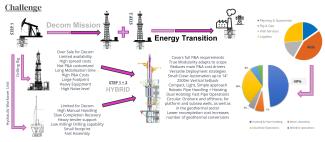

Key Challenges Addressed:

- Inefficient Decommissioning: The Lean Machine is designed to tackle the inefficiencies plaguing the decommissioning of existing infrastructure, currently hindered by outdated supply chain equipment ill-equipped to manage uncertainties cost-effectively.

- Operational Costs: In response to soaring operational expenses in offshore activities, the Lean Machine provides an innovative alternative to conventional supply chain options and specialized production-enhancement equipment.

- Environmental Impact: With a strong emphasis on reducing environmental footprints and enhancing health and safety standards, the Lean Machine aligns with the evolving energy transition.

Technical and Commercial Objectives:

The Lean Machine aspires to achieve a range of technical, operational, and commercial goals:

- Efficiency Enhancement: Offering a groundbreaking approach to offshore operations, this technology significantly enhances efficiency through its dual hoisting system, making it adaptable to address uncertain well delivery programs and deployment methods.

- Environmental Responsibility: The Lean Machine embeds environmental responsibility within its design. Achieving this through reduced weight, a smaller footprint, an energy recovery system, and streamlined processes to minimize waste and environmental impact.

- Versatility: Its adaptability across various offshore activities positions the Lean Machine as a cost-effective and versatile solution, ideal for a wide range of projects.

- Cost Reduction: This innovative technology reduces reliance on outdated supply chain options, instead leveraging modular designs to generate substantial cost savings.

Game-Changing Features:

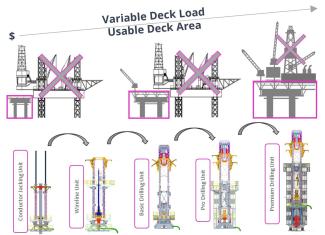

The Lean Machine's signature feature is its adaptable, modular design, in combination with a compact, automated dual hoisting system. It can be tailored to meet specific project requirements, offering solutions ranging from conductor pulling to lightweight and heavy-duty drilling. This adaptability establishes a new industry standard for versatility, efficiency, and cost-effectiveness.

Contributions to Industry Challenges:

In the oil & gas, CCUS, hydrogen, and renewables sectors, the Lean Machine addresses a multitude of challenges. It streamlines decommissioning operations by mobilizing only the necessary equipment for specific tasks, effectively reducing costs and minimizing waste. Its versatility extends to enabling well repurposing for a cost-efficient energy transition, making it suitable for various applications within the energy sector.

Business Case:

The Lean Machine is not only an environmental champion; it's also an economic powerhouse. Its flexible, rapid deployment capability allows access to smaller platforms, often only reachable by Jackups. Competing head-to-head with Jackup capabilities at HWU dayrates, it significantly reduces operational costs. This competitive advantage extends to lower project expenses, environmental benefits, and enhanced health and safety, all contributing to a positive industry image and regulatory compliance.

In summary, the Lean Machine presents a hybrid versatile modular solution that bridges a hydraulic workover unit and a modular drilling system, offering rapid assembly and a compact, lightweight footprint. It excels in pipe handling efficiency, surpassing the hoisting capacities of other systems through its dual hoisting design. This innovation offers effective solutions for a broad spectrum of offshore activities, addressing critical industry challenges while making substantial contributions to cost reduction, improved environmental impact, and health and safety performance. The Lean Machine possesses the potential to be a true game-changer within the offshore energy sector, propelling the industry toward a more sustainable and prosperous future.

| Specification Title | Specification Description |

|---|---|

|

Hook Load:

|

350sht

|

|

Top Drive:

|

31,000ftlbs @60 RPM

|

|

Tripping speed:

|

900m/hr

|

|

Dead weight:

|

120mt

|

|

Footprint

|

2x 20ft ISO Container

|

|

Assembly:

|

48 hrs

|

|

120kNm Iron Roughneck:

|

2 3/8" - 9 5/8"

|

|

Fingerboard:

|

3000m API Range 3

|

|

Lifting weight:

|

Max. 12mt

|

|

Transport:

|

2.5m x 2.7m x 12m

|

|

False Rotary:

|

37.5"

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[5/9]