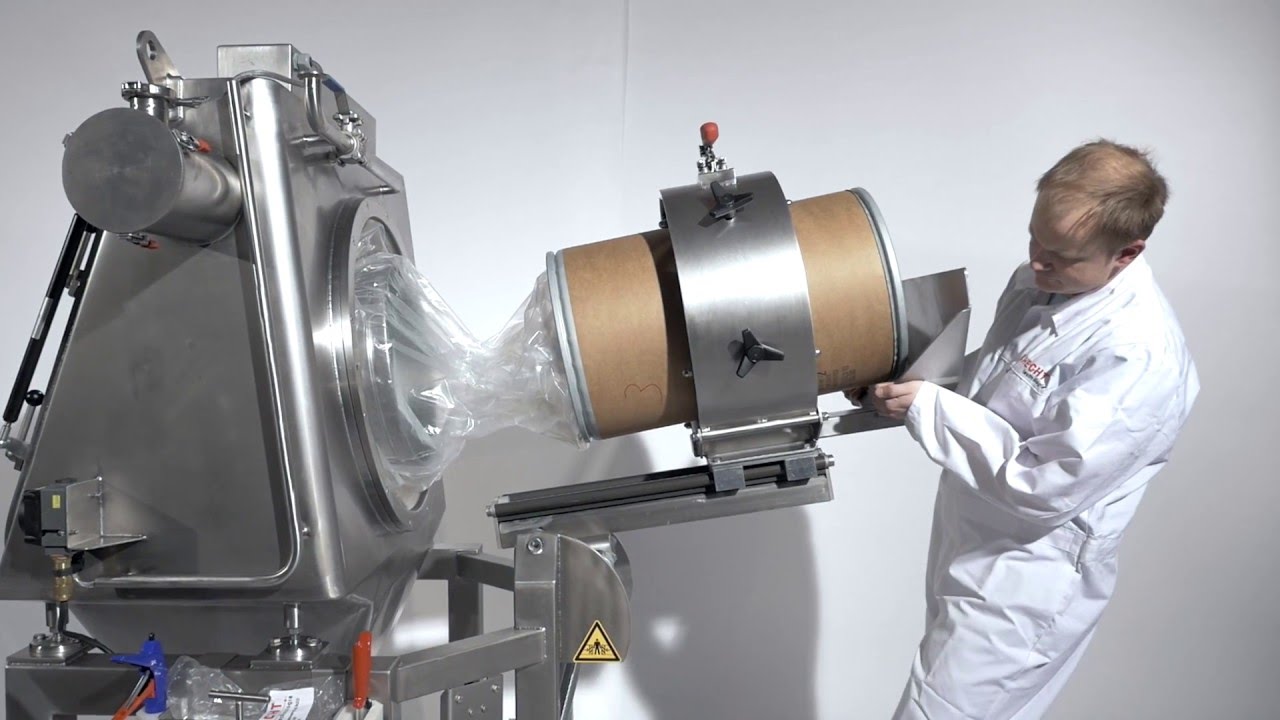

The containment barrel emptying with tipper

Low-contamination emptying of barrels with inliners up to OEB 5

The containment barrel emptying with tipper type CFE-K from HECHT is used for low-contamination emptying of barrels with inliners up to OEB 5. With the help of the tilting device for barrels, they can be docked effortlessly.

The products delivered in barrels are additionally packaged in foil, also known as liners, for operator and product protection. The product must be packed in at least a liner.

In the variant with a tilting device, the barrel is lifted using a special lifting device on the back of the glovebox and docked at the connection port provided. In the starting position, a rest liner closes the glovebox. The user fixes the outer film tube to the double O-ring port of the insulator via the residual liner. The operator then pulls the remaining liner into the insulator using the gloves. Now he pulls the clamping ring onto the outer groove of the insulator, where the residual liner was previously located, and pushes the barrel opening into the insulator. In the isolator he opens the inner liner and empties the contents using the gloves. Through the glovebox, the bulk material can now reach the next process step using gravity. Of course, if desired, a suction shoe can alternatively be integrated at the bottom of the funnel for connection to a downstream vacuum conveyor.

After emptying the contents, the film tube is sealed to the barrel and insulator using a double closure. This double closure technology protects both the insulator and the product from unwanted product leakage (or entry). The cycle can now begin again and a new barrel can be connected.

| Specification Title | Specification Description |

|---|---|

|

areas of application

|

bulk handling

|

|

markets

|

pharma chemical battery food waste

|

|

capacity

|

capacity rated to customers request

|

|

certifications

|

atex ehedg fda gmp

|

|

compliance

|

international guidelines on request

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[9/9]

Relative Business Impact

Sign up or log in to your explorer or higher plan to get access to all the 1 deployment references.

Last Deployment Year