CIAS (Corrosion Inhibited Anti-Scale)

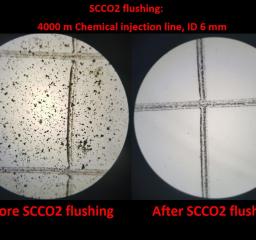

In-line De-scaling Program in Live Hydrocarbon Systems Onshore & Offshore

The Challenge:

Production Losses due to Calcium Carbonate Scale and Associated Shutdown/TAR De-Scaling Remediation Costs.

Calcium carbonates causes major problems in many technical systems, e.g. oil processes on production platforms. Scale often builds up in SSSVs in wells and master, wing and choke valves on Xmas trees. It also commonly occurs in flow lines, produced water systems, separators, flair drums, hydro-cyclones, coolers, heat exchangers, cooling water systems etc.

The Negative Effects of Scale

Scale negatively affects process performance by reducing flow, increasing pressure drop, impairing heat transfer or, in the worst case, causing blockades, corrosion or leaks. Oil production is thus considerably reduced and, eventually a shutdown/TAR becomes unavoidable.

The Solution:

IKM Ocean Team proprietary CIAS Technology (Corrosion Inhibited Anti-Scale) - De-Scaling of Live Systems

With over 20 years track record in Denmark, IKM Ocean Team has extensive knowledge and experience with de-scaling of live process and cooling systems. This unique cleaning process does not require a production shutdown/TAR. This is a huge advantage compared to conventional chemical cleaning methods, which require shutdown/TAR during cleaning.

| Specification Title | Specification Description |

|---|---|

|

Capabilities

|

Optimizes O&G production instantly by removing scale from live production systems | Proven track record from many years of non stop operations on various offshore installations.

|

|

Certification/ Licenses

|

Equipment complies with ATEX zone II | DNV approved and periodically inspected.

|

|

Compliance

|

EC Directive 2006/42/EC, Machinery Directive | EC Directive 2004/108/EC, Electromagnetic compatibility (EMC) | EC Directive 97/23/EC, Pressurized Equipment Directive | EC Directive 94/9/EC, ATEX Directive.

|

|

Documentation

|

Full documentation package to cover every component.

|

|

Maintenance

|

Equipment undergoes maintenance periodically resulting in high reliability and safety.

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[9/9]

Relative Business Impact

Sign up or log in to your explorer or higher plan to get access to all the 3 deployment references.

Last Deployment Year