WELLBORE SEALING USING M3 BISMUTH ALLOYS

Improved sealing technologies for the energy industries

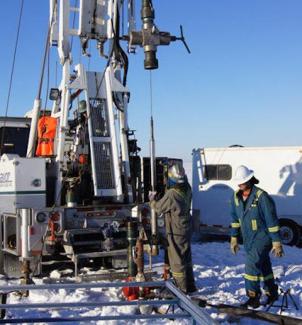

One of the most challenging aspects of developing a bismuth plug is the tool string necessary to deploy the plug downhole – In particular how to provide sufficient heat to melt the alloy once at the required depth.

The typical approach for the downhole heating of alloys is to use an exothermic chemical reaction – namely derivatives of Thermite. These burn incredibly hot. Custom formulations can be dampened and controlled up to a point. However, these still burn pretty quick and hot – and this can cause many issues.

Wellstrøm has developed electrical heaters and cables with sufficient strength and capacity to provide a controllable heating solution – operating at much lower temperatures for a longer time, slowly warm-up the casing, annulus and even the formation if required.

| Specification Title | Specification Description |

|---|---|

|

Areas of Application

|

Plugging & Abandonment | Sealing leaks in Civil Structures | Industrial Pipelines | Developing Bespoke Solutions

|

|

Available Sizes

|

Multiple sizes 7” to 36” OD, to serve the needs of different well/reservoir conditions

|

|

Plug Setting

|

The Company’s tool is capable in setting plugs inside tubing or production casings up to 10-3/4in.

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[8/9]

Relative Business Impact

Sign up or log in to your explorer or higher plan to get access to all the 1 deployment references.

Last Deployment Year