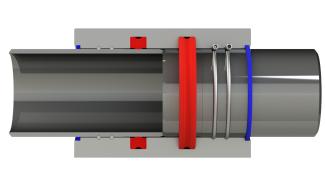

SRJ Pipe Coupling

Weldless pipe connector

SRJ Weld-free Pipe Coupling solves many of the problems commonly associated with welded and flanged joints in process piping. It is weld-free, lightweight, quick to install, and provides a high integrity connection. It can be used as a temporary or permanent solution in both new lay and established pipework.

Time and cost of installation: substantial amount of process and labour costs can be saved by negating welding and weld-related activities.

Minimum maintenance: bolt-free design demands no fabric maintenance or bolt retorquing.

Practicality: allows for multiple dis-assemblies and re-assemblies over its lifetime.

Speed: up to 90% faster to assemble and disassemble a spool vs a flanged connection.

Lightweight: one SRJ Coupling is circa 30% lighter than the two comparative bolted flanges.

Compact design: significant space savings compared to a flanged connection

| Specification Title | Specification Description |

|---|---|

|

Application

|

SRJ Coupling enables time efficient spool replacement or modular tie in, and rapid equipment change-out (e.g., PSV). Suitable for both Brownfield and Greenfield applications.

|

|

Areas of Application

|

Oil & Gas | Desalination | Mining | Utilities | Shipping | Power Generation

|

|

Certifications / licences

|

Designed in accordance with ASME B31.3 | Fire rated product Type Approved by ABS and Lloyd's Register for hydrocarbon applications

|

|

Dimension

|

Weighs less than a third of the equivalent flange

|

|

Installation

|

Does not introduce added stress to the pipe (unlike ball-grip mechanical couplings)

|

|

Material

|

Carbon Steel as standard; other grades of steel available on request

|

|

Pipe diameter

|

ABS and LR Type Approved for 1.25" to 16" nominal pipe sizes including hydrocarbon service.

|

|

Pressure class

|

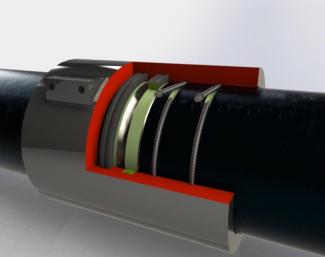

Internal seals retain the internal pressure of the pipe | Energised once the pipe is under pressure | Suitable for a range of pipe media | Replaceable | Available with localised reverse pressure testing functionality

|

|

Product

|

Multiple configurations to address different piping system needs (pipe to pipe, pipe to flange, blind end, reducer, etc)

|

|

Protection

|

Prevents ingress of external impurities | Protects retaining wires by blocking access to the internal bore of the coupling

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[9/9]

Relative Business Impact

Sign up or log in to your explorer or higher plan to get access to all the 1 deployment references.

Last Deployment Year