In-Service Pipe Lifts

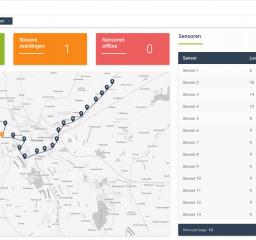

Ovolifts enables proactive management of corrosion under pipe supports

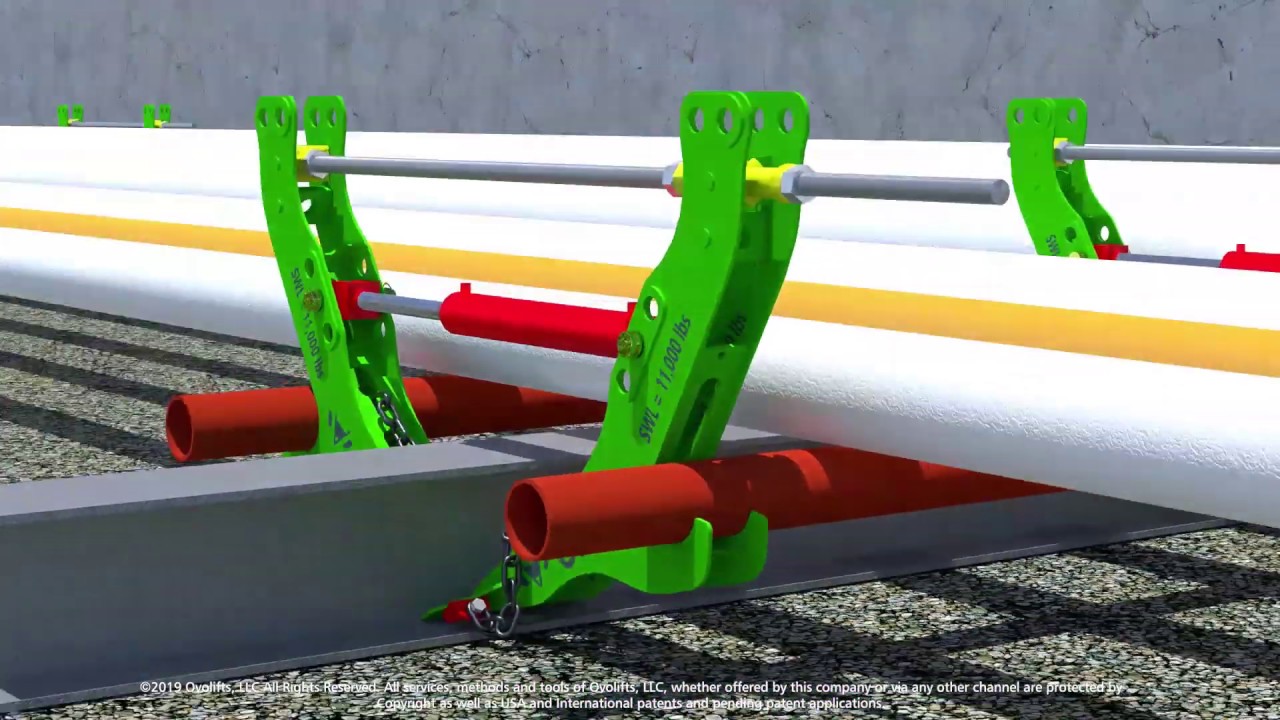

Our pipe lifting system enables inspection and corrosion prevention maintenance on multiple pipe touchpoints whilst the lines are in-service and averts costly plant & terminal shutdowns or extended turnarounds. In the past 18 months Ovolifts’ clients have extended the useful life of their critical assets without operational interruptions, resulting in time and costs savings of millions of dollars. Cost-effective interventions such as these will contribute significantly to rebuilding the financial strength of the petrochemical industry in a post Covid-19 environment.

Safe for people:

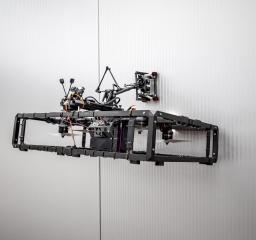

- Remote activation.

- Safe access below, not a suspended load.

- Spark free.

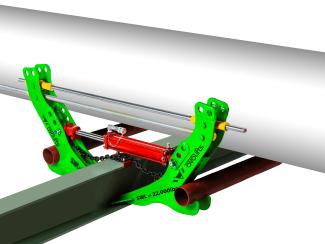

- Light-weight and certified equipment.

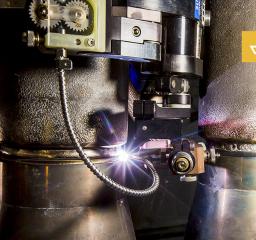

Safe for equipment:

- Controlled lifting.

- Backed by engineering through calculations on pipe stress curves and jack layouts.

- Backed by safety procedures and reaction planning.

- Loss of containment planning and identification.

Financial benefits:

- No shutdown required.

- Access to multiple touch points.

- Access to supports.

- Easy assembly of tools.

- Can be installed with rope access thus not scaffolding.

| Specification Title | Specification Description |

|---|---|

|

Areas of Application

|

Pipe racks or pipelines in chemical facilities and storage terminals.

|

|

Asset life extension

|

Planned maintenance replaces unplanned emergency work.

|

|

Certifications / licences

|

Lifting equipment is tested and certified for use. Technicians using equipment receive training before being certified to handle and operate the jacks.

|

|

Compatibility

|

Lift from any type of supporting beam such as I-beams, concrete sleepers, circular supports or channel beams etc.

|

|

Economic Tools

|

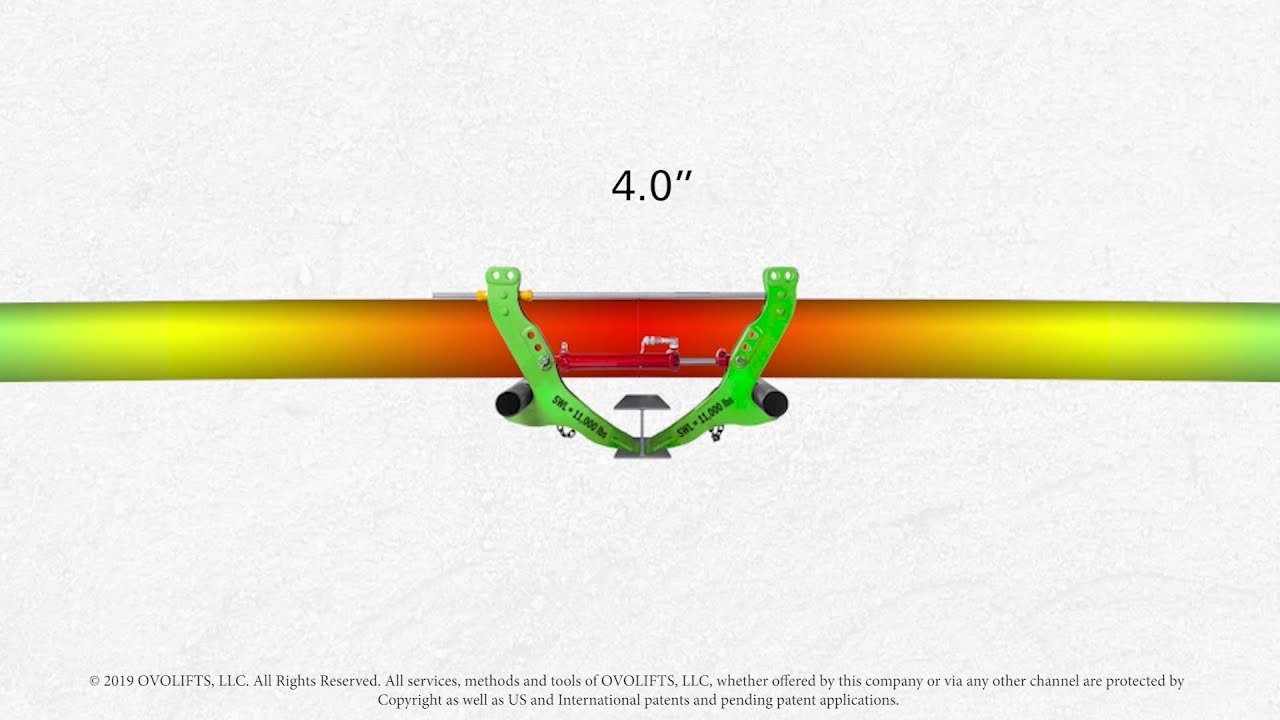

Pipe stress analysis ensures pipe stresses during lifting remain within allowable limits and a lift plan details the lifting procedures.

|

|

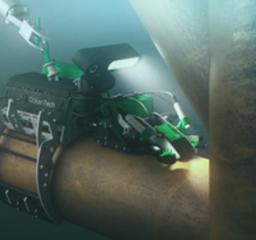

In-service inspection possible

|

Remote lifting, static structure and pipe stress analysis enables safe use on live equipment.

|

|

Patents

|

US and international patent protected.

|

|

Pipe diameter

|

Applicable to any pipe diameter.

|

|

Safety

|

Remote lifting and static structures.

|

Reviews (1)

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[9/9]

Relative Business Impact

Sign up or log in to your explorer or higher plan to get access to all the 5 deployment references.

Last Deployment Year