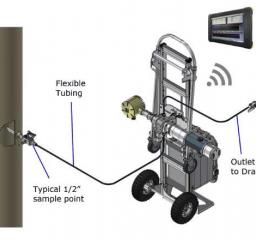

Real-Time Acoustic Sand Monitoring

Non-intrusive instantaneous response to sand production

Over time, sand will cause damage to plant and equipment on a platform, Left unchecked it can be responsible for loss of primary containment, creating the possibility of explosion and serious injury. In all cases, sand erosion results in loss of efficiency, downtime and reduced production.

Quickly identifying the presence of sand gives you the opportunity to adjust production, reduce maintenance and minimise potential equipment damage.

Accurate monitoring coupled with analysis and interpretation of the real time data means improved longevity of your assets and reduces costly repairs, replacement and downtime. Depending on the data output required we can also provide expert analysis to interpret the information provided.

We offer training, support and maintenance in the operation of monitoring systems and provide expertise to input the right set up information (flow, speed etc) to make sure the data you receive is correct and accurate.

| Specification Title | Specification Description |

|---|---|

|

Particle Detection Limit

|

15-25μm varies with flow regime, velocity, viscosity etc

|

|

Output

|

grams/second (g/s)

|

|

Pipe Dimension

|

≥2”

|

|

Flow Velocity

|

Min 1m/s for most flow regimes

|

|

Uncertainty

|

+/- 5% (dependent)

|

|

Remote Monitoring

|

SMS engineers can monitor equipment remotely when required

|

|

Data storage

|

Up to 9-90 days in flash memory

|

|

Communication

|

Two wire RS485, Modbus RTU, baud rate configurable

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[9/9]

Relative Business Impact

Sign up or log in to your explorer or higher plan to get access to all the 2 deployment references.

Last Deployment Year