Multifunctional Production Unit

An all encompassing solution for low pressure matured wells

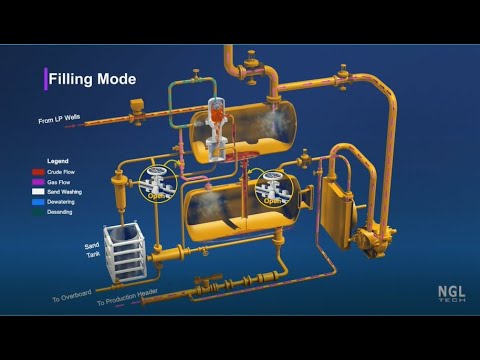

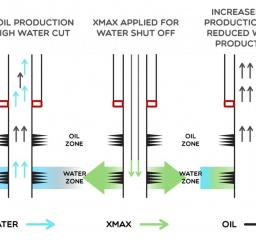

The Multi Production Unit (MPU) is a low pressure production system with integral desanding and bulk dewatering capabilities. The MPU is designed to boost the pressure of production fluids from low pressure wells, while handling common challenges in mature fields such as high water cut and high sand production. The system is ideally suited for remote wellhead platforms where wells have insufficient pressure to deliver well fluids to production header in addition to flow assurance issues related to high sand and high water production.

MPU technology is the winner of "Spotlight Technology Award" for OTC Asia 2020.

| Specification Title | Specification Description |

|---|---|

|

Footprint

|

Flexible design based on capacity - Range from 8 tons to 20 tons

|

|

Certification

|

Electronic parts are ATEX certified as explosion proof/Flame proof (Exd) or Intrinsically safe (Ex ia)

|

|

Hazardous Area Classification

|

Zone 0 and above

|

|

Capacity

|

Unlimited. Skid design can be adapted to any flowrate.

|

|

Validation

|

U-stamped pressure vessels. DOSH registered equipment. API relief system.

|

|

Automation

|

Standard design is fully automated via Allen Bradley unit control panel, yet it can be integrated with different systems.

|

|

Material of Construction

|

Can be specified to suit existing facility metallurgy

|

|

Location

|

Fit for Remote Wellhead Platform, and Central Processing Platforms.

|

|

Turndown

|

High tolerance for production turndown to 0%

|

|

Specialty Equipment

|

Optional acoustic sand detectors with an analyzer software, optional oil-in-water analyzers

|

|

Efficiency

|

High sand removal efficiency targeting 20 microns and above. Dewatering spec Oil-In-Water < 30 ppm.

|

|

Pressure Rating

|

Flexible. Fit for 150# up to 2500#.

|

|

Auxiliary Systems

|

Optional sand washing package for dumping sand overboard.

|

|

CAPEX

|

Bulk water separation at the wellhead side allows for debottlenecking of downstream facilities

|

|

OPEX

|

Reduces chemical injection and asset depreciation due to erosion

|

|

Recognition

|

'Spotlight Technology Award' OTC Asia 2020

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[7/9]