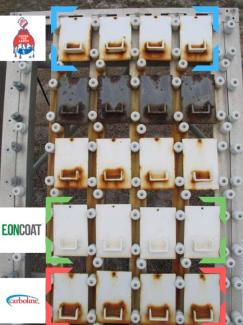

EonCoat Corrosion Protection Coating

Permanent Corrosion Protection Solution for Carbon Steel

EonCoat is the only patented, spray-applied carbon steel treatment that permanently prevents corrosion and offers a 30-year warranty. Today, most rust prevention treatments on the market lay on top of carbon steel. EonCoat has solved the rust problem, and that is why we are both different and better. EonCoat bonds to the carbon steel with one layer and then re-inforces that protection with a layer of chemically-bonded phosphate ceramic.

Our Research and Development Team specifically engineered EonCoat to be safe for both the environment and the applicators in the field. EonCoat is an inorganic, water-based coating. As a result, our products have NO VOCs, NO HAPs, NO toxins, and No odor.

EonCoat has two parts – Part A and Part B. It’s easy to remember because one is an Acid and the other is a Base. When the two parts meet in a dual-component spray gun or high-pressure plural pump and reach the carbon steel, a chemical bond occurs. The bonded EonCoat will be dry-to-the-touch in 5 minutes and air-cured in 15 minutes.

| Specification Title | Specification Description |

|---|---|

|

Areas of Application

|

Storage Tanks, Pipelines, Insulated Tanks, Insulated Pipelines, & Sweating Pipelines

|

|

Life Expectancy

|

Once EonCoat is applied is should last the life of the asset.

|

|

Surface Preparation

|

NACE 3 / SSPC-SP6 / SA 2 Commercial Blast is required, but no hold blast is required. EonCoat can be applied over the top of surface rust

|

|

Application & Cure Time

|

Sprayed at a 1:1 ratio the chemical reaction causes EonCoat to bond to steel and cure in 15 min.

|

|

Safety

|

Very Safe for workers. No exposure to VOCs, HAPs, Toxins, or odors

|

|

Environment

|

Water-based coating leaves no carbon foot print. No solvents needed for cleaning equipment & no hazardous procedures needed for disposing EonCoat

|

|

Application Conditions

|

Humidity & Salt Levels do not effect EonCoat performance.

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[9/9]

Relative Business Impact

Sign up or log in to your explorer or higher plan to get access to all the 1 deployment references.

Last Deployment Year