EMA-3T

NextGen Ultrasonic Thickness Gauge

Digitalization provides deeper insights to enable process optimization and reduction/elimination of human-error, leading to a smarter way of working and reducing cost.

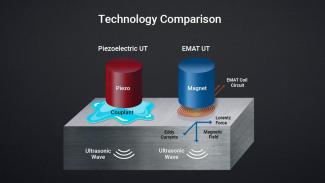

EMA-3T is an ultrasonic thickness gauge which was designed with the core principles of Industry 4.0 and ready for the future of inspections. First of its kind addressing the inspection process from start to end. A digital device using custom inspection workflows to facilitate inspections; integrated RFID and Barcode technology for asset identification; EMA technology that eliminates the limitations of piezoelectric based UT gauges and provides connectivity with its IIoT capabilities.

| Specification Title | Specification Description |

|---|---|

|

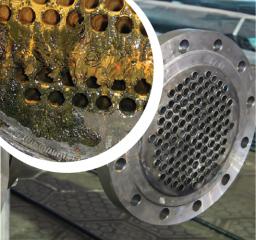

Areas of Application

|

Oil and Gas | Utilities | General Non-destructive thickness services

|

|

Capabilities

|

No surface preparation, contact, gel or specific alignment required. Able to identify assets though RFID & barcode readers.

|

|

Efficiency

|

EMA-3T testing has demonstrated time savings of 60% on high pressure piping and 75% on complete equipment assemblies.

|

|

Inspection

|

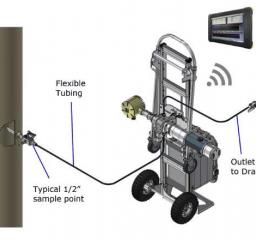

User only required to scan assets and inspection workflows are loaded to guide the user through the process. All recorded data are saved in a structured format.

|

|

Connectivity

|

Instant connectivity based on its IIoT architecture allowing data to be exchanged via USB cable, Wi-Fi or Bluetooth.

|

|

Ergonomic design

|

Fits comfortably in the hand of the user, clear screen visbility even in direct sunlight and weighing 830 grams.

|

|

Environmental rating

|

Operating temperature -20 to +50 °C, IP65 and 6 hours operating time on a full charge.

|

|

ATEX certified

|

Not yet ATEX qualified.

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[9/9]

Relative Business Impact

Sign up or log in to your explorer or higher plan to get access to all the 1 deployment references.

Last Deployment Year